A588GrA steel plate is a low carbon steel with good corrosion resistance. Its anti-corrosion performance is composed of rich chromium, manganese, copper and sil

Q355NH corten steel is a type of weathering steel that possesses excellent corrosion resistance and durability in harsh environments. It can withstand exposure

Steel sheet S355J2W is a high-strength, low-alloy structural steel that offers excellent corrosion resistance and aesthetic appeal. Its weathering properties ma

X80 pipeline steel has very strict requirements on the control of harmful elements and inclusions in the steel. In production, the production process of refinin

The performance of X70 pipeline steel mainly depends on its chemical composition and structure. Inclusions in X70 pipeline steel mainly exist in the form of non

In the fierce market competition, all oil companies in the world are constantly looking for ways to reduce costs and improve efficiency.In the investment of pip

With the improvement of quality requirements for rolled products, and the application of new technologies and equipment, it could be changed in every step of ro

Among the many factors of affecting the non-metallic inclusions in SM570 molten steel, the weak stirring of SM570 molten steel and the sedation time of SM570 mo

Pickling: The process of using acid solution to remove scale and rust on the surface for SM570 steel plate is called pickling. It is a method of cleaning the me

It is easy to produce a hardened structure, if the cooling rate of P235GH steel is too fast during welding, and the interlayer brittleness increases, it will le

When the production is completed, what are the acceptance criteria for the surface of the P235GH steel plate?1. The surface of P235GH steel plate should be free

It is inevitable that there will be different problems in the production process of the steel plate. What defects may appear on P235GH steel plate?(1) Cracks. I

When the welding process of X80 pipeline steel is unreasonable, or the number of inclusions in the base metal is large, the shape and distribution are uneven, c

According to the sources, the inclusions in X70 pipeline steel can be divided into two categories: endogenous and exogenous. Among them, the endogenous inclusio

·Different standards

a.API5CT: It is an oil casing standard issued by the American Petroleum Institute.

b. API5L: refers to API 5L line pipe, which is th

A515 Gr60 steel is a carbon-silicon-killed steel plate primarily used for high-temperature service in welded boilers and other pressure vessels.In terms of stre

A515 Gr70 is a high-strength steel commonly used for pressure vessels in various industries such as oil and gas, petrochemical, and power generation. It has a m

Inclusions in X70 pipeline steel mainly exist in the form of non-metallic compounds, such as oxides, sulfides, nitrides, etc. Non-metallic inclusions have a gre

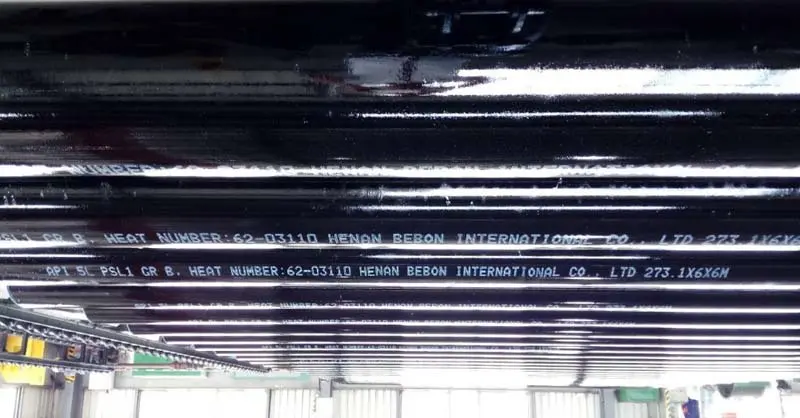

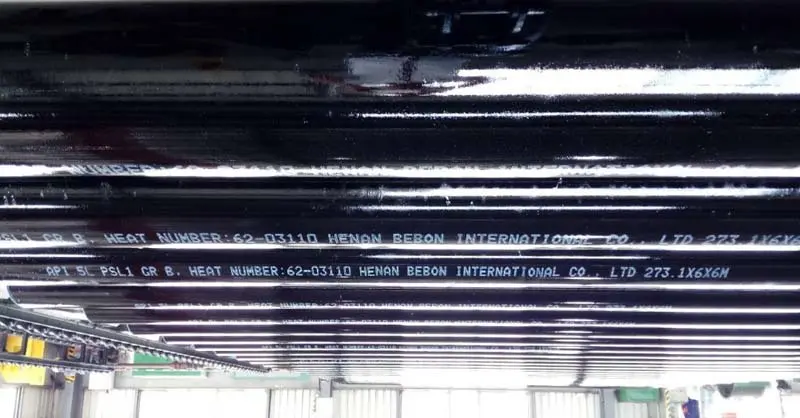

In the API 5L steel pipe standard, the quality standards (or requirements) of steel pipes are divided into PSL1 and PSL2. PSL is an abbreviation for product spe

"X" in the X52 stee designation indicates pipeline steel, and "52" indicates that the minimum yield strength value of the steel plate is 52ksi (1ksi=6.895Mpa).

D36 steel plate is a high-strength structural steel used in offshore and marine applications. It is typically used for hull structures and provides excellent we

There are several alternative steel materials to ABS grade A plate, including:1. ASTM A36 steel plate: This is a commonly used mild steel plate that has good st

API 5L generally refers to the implementation standard of pipeline pipes, which include seamless steel pipes and welded steel pipes.The national standard GB/T 9

1.There should be no cracks, scars, folds, air bubbles, inclusions, and visually visible delaminations on the surface of X52 steel plates that are harmful to us

The basic production processes of API 5L X60 pipeline steel mainly include: conventional semi-continuous hot rolling, CSP continuous casting and rolling, medium

Contact us

Contact us

Products

Products News

News You are here : BEBON STEEL - News

You are here : BEBON STEEL - News A588GrA steel plate is a low carbon steel with good corrosion resistance. Its anti-corrosion performance is composed of rich chromium, manganese, copper and sil

A588GrA steel plate is a low carbon steel with good corrosion resistance. Its anti-corrosion performance is composed of rich chromium, manganese, copper and sil Q355NH corten steel is a type of weathering steel that possesses excellent corrosion resistance and durability in harsh environments. It can withstand exposure

Q355NH corten steel is a type of weathering steel that possesses excellent corrosion resistance and durability in harsh environments. It can withstand exposure Steel sheet S355J2W is a high-strength, low-alloy structural steel that offers excellent corrosion resistance and aesthetic appeal. Its weathering properties ma

Steel sheet S355J2W is a high-strength, low-alloy structural steel that offers excellent corrosion resistance and aesthetic appeal. Its weathering properties ma X80 pipeline steel has very strict requirements on the control of harmful elements and inclusions in the steel. In production, the production process of refinin

X80 pipeline steel has very strict requirements on the control of harmful elements and inclusions in the steel. In production, the production process of refinin The performance of X70 pipeline steel mainly depends on its chemical composition and structure. Inclusions in X70 pipeline steel mainly exist in the form of non

The performance of X70 pipeline steel mainly depends on its chemical composition and structure. Inclusions in X70 pipeline steel mainly exist in the form of non In the fierce market competition, all oil companies in the world are constantly looking for ways to reduce costs and improve efficiency.In the investment of pip

In the fierce market competition, all oil companies in the world are constantly looking for ways to reduce costs and improve efficiency.In the investment of pip With the improvement of quality requirements for rolled products, and the application of new technologies and equipment, it could be changed in every step of ro

With the improvement of quality requirements for rolled products, and the application of new technologies and equipment, it could be changed in every step of ro Among the many factors of affecting the non-metallic inclusions in SM570 molten steel, the weak stirring of SM570 molten steel and the sedation time of SM570 mo

Among the many factors of affecting the non-metallic inclusions in SM570 molten steel, the weak stirring of SM570 molten steel and the sedation time of SM570 mo Pickling: The process of using acid solution to remove scale and rust on the surface for SM570 steel plate is called pickling. It is a method of cleaning the me

Pickling: The process of using acid solution to remove scale and rust on the surface for SM570 steel plate is called pickling. It is a method of cleaning the me It is easy to produce a hardened structure, if the cooling rate of P235GH steel is too fast during welding, and the interlayer brittleness increases, it will le

It is easy to produce a hardened structure, if the cooling rate of P235GH steel is too fast during welding, and the interlayer brittleness increases, it will le When the production is completed, what are the acceptance criteria for the surface of the P235GH steel plate?1. The surface of P235GH steel plate should be free

When the production is completed, what are the acceptance criteria for the surface of the P235GH steel plate?1. The surface of P235GH steel plate should be free It is inevitable that there will be different problems in the production process of the steel plate. What defects may appear on P235GH steel plate?(1) Cracks. I

It is inevitable that there will be different problems in the production process of the steel plate. What defects may appear on P235GH steel plate?(1) Cracks. I When the welding process of X80 pipeline steel is unreasonable, or the number of inclusions in the base metal is large, the shape and distribution are uneven, c

When the welding process of X80 pipeline steel is unreasonable, or the number of inclusions in the base metal is large, the shape and distribution are uneven, c According to the sources, the inclusions in X70 pipeline steel can be divided into two categories: endogenous and exogenous. Among them, the endogenous inclusio

According to the sources, the inclusions in X70 pipeline steel can be divided into two categories: endogenous and exogenous. Among them, the endogenous inclusio ·Different standards

·Different standards A515 Gr60 steel is a carbon-silicon-killed steel plate primarily used for high-temperature service in welded boilers and other pressure vessels.In terms of stre

A515 Gr60 steel is a carbon-silicon-killed steel plate primarily used for high-temperature service in welded boilers and other pressure vessels.In terms of stre A515 Gr70 is a high-strength steel commonly used for pressure vessels in various industries such as oil and gas, petrochemical, and power generation. It has a m

A515 Gr70 is a high-strength steel commonly used for pressure vessels in various industries such as oil and gas, petrochemical, and power generation. It has a m Inclusions in X70 pipeline steel mainly exist in the form of non-metallic compounds, such as oxides, sulfides, nitrides, etc. Non-metallic inclusions have a gre

Inclusions in X70 pipeline steel mainly exist in the form of non-metallic compounds, such as oxides, sulfides, nitrides, etc. Non-metallic inclusions have a gre In the API 5L steel pipe standard, the quality standards (or requirements) of steel pipes are divided into PSL1 and PSL2. PSL is an abbreviation for product spe

In the API 5L steel pipe standard, the quality standards (or requirements) of steel pipes are divided into PSL1 and PSL2. PSL is an abbreviation for product spe "X" in the X52 stee designation indicates pipeline steel, and "52" indicates that the minimum yield strength value of the steel plate is 52ksi (1ksi=6.895Mpa).

"X" in the X52 stee designation indicates pipeline steel, and "52" indicates that the minimum yield strength value of the steel plate is 52ksi (1ksi=6.895Mpa). D36 steel plate is a high-strength structural steel used in offshore and marine applications. It is typically used for hull structures and provides excellent we

D36 steel plate is a high-strength structural steel used in offshore and marine applications. It is typically used for hull structures and provides excellent we There are several alternative steel materials to ABS grade A plate, including:1. ASTM A36 steel plate: This is a commonly used mild steel plate that has good st

There are several alternative steel materials to ABS grade A plate, including:1. ASTM A36 steel plate: This is a commonly used mild steel plate that has good st API 5L generally refers to the implementation standard of pipeline pipes, which include seamless steel pipes and welded steel pipes.The national standard GB/T 9

API 5L generally refers to the implementation standard of pipeline pipes, which include seamless steel pipes and welded steel pipes.The national standard GB/T 9 1.There should be no cracks, scars, folds, air bubbles, inclusions, and visually visible delaminations on the surface of X52 steel plates that are harmful to us

1.There should be no cracks, scars, folds, air bubbles, inclusions, and visually visible delaminations on the surface of X52 steel plates that are harmful to us The basic production processes of API 5L X60 pipeline steel mainly include: conventional semi-continuous hot rolling, CSP continuous casting and rolling, medium

The basic production processes of API 5L X60 pipeline steel mainly include: conventional semi-continuous hot rolling, CSP continuous casting and rolling, medium